The Ultimate Buying Guide for Torque Screwdrivers: Types, Key Considerations, Features, Prices, Tips, and FAQs

Overview

A torque screwdriver is a precision tool that is used to apply a specific amount of torque to a screw. It is an essential tool for anyone who needs to tighten screws to a specific torque level, such as mechanics, technicians, and DIY enthusiasts. In this buying guide, we will discuss the different types of torque screwdrivers, key considerations when choosing a torque screwdriver, features to look for, prices, tips on using a torque screwdriver, and frequently asked questions.

Types

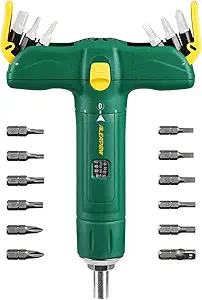

1. Adjustable torque screwdriver: This type of torque screwdriver allows you to adjust the torque level to suit your needs. It is ideal for applications where you need to apply different torque levels to different screws.

2. Precision torque screwdriver: This type of torque screwdriver is designed for applications that require a high level of precision, such as electronics and medical devices.

3. Electronic torque screwdriver: This type of torque screwdriver features a digital display that shows the applied torque level. It is ideal for applications where accuracy is crucial.

4. Torque limiting screwdriver: This type of torque screwdriver is designed to prevent over-tightening of screws. It is ideal for applications where over-tightening can cause damage or failure.

5. Cordless torque screwdriver: This type of torque screwdriver is powered by a rechargeable battery and is ideal for applications where mobility is important.

Key Considerations

1. Torque range: The torque range of a torque screwdriver should match the torque requirements of your application.

2. Accuracy: The accuracy of a torque screwdriver is crucial for applications where precision is important.

3. Durability: A torque screwdriver should be durable enough to withstand regular use without breaking or malfunctioning.

4. Ergonomics: A torque screwdriver should be comfortable to hold and use for extended periods.

Features

1. Torque adjustment: An adjustable torque screwdriver should have an easy-to-use torque adjustment mechanism.

2. Digital display: An electronic torque screwdriver should have a clear and easy-to-read digital display.

3. Calibration: A torque screwdriver should be easy to calibrate to ensure accuracy.

4. Grip: A torque screwdriver should have a comfortable and non-slip grip.

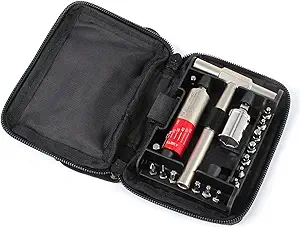

5. Storage: A torque screwdriver should come with a storage case to protect it when not in use.

Prices

Torque screwdrivers range in price from around $20 for a basic manual torque screwdriver to over $500 for a high-end electronic torque screwdriver.

Tips

1. Always follow the manufacturer's instructions when using a torque screwdriver.

2. Use the right torque setting for each screw to avoid over-tightening or under-tightening.

3. Store your torque screwdriver in a dry and cool place to prevent damage.

FAQs

Q: What is a torque screwdriver used for?

A: A torque screwdriver is used to apply a specific amount of torque to a screw.

Q: What is the difference between a torque screwdriver and a regular screwdriver?

A: A torque screwdriver is designed to apply a specific amount of torque to a screw, while a regular screwdriver does not have this feature.

Q: Can I use a torque screwdriver for all types of screws?

A: No, you should use a torque screwdriver only for screws that require a specific torque level.

Q: How do I calibrate my torque screwdriver?

A: Refer to the manufacturer's instructions for calibration procedures.